CAPABILITIES

Material Supply & Preparation

Reliable Manufacturing Starts With Reliable Materials

For large global OEMs, material supply is more than just procurement, it’s a core enabler of programme stability and cost control. A single delay, mislabelled batch, or uncertified alloy can jeopardise entire production schedules, impacting multiple tiers of the supply chain.

High-Performance Manufacturing

Precision Manufacturing Starts Long Before the First Component is Machined

As the first stage in our vertically integrated process, Material Supply & Preparation creates the foundation for accuracy, quality and predictable delivery. We source certified materials, verify compliance on arrival and prepare stock with full digital traceability.

By controlling this critical stage in-house, we eliminate uncertainty, reduce lead-time risk and ensure every programme begins with proven, specification-aligned material. This guarantees consistency for machining, fabrication and surface treatment downstream.

Lorem Ipsum

XXX%

How We Do It

Material Supply Chain Management

At BCW, we control the entire material supply chain in-house to ensure quality, continuity and confidence from day one. Materials are sourced only from ISO 9001, AS9100 and IATF 16949 certified suppliers, with PMI verification and certification checks completed on receipt.

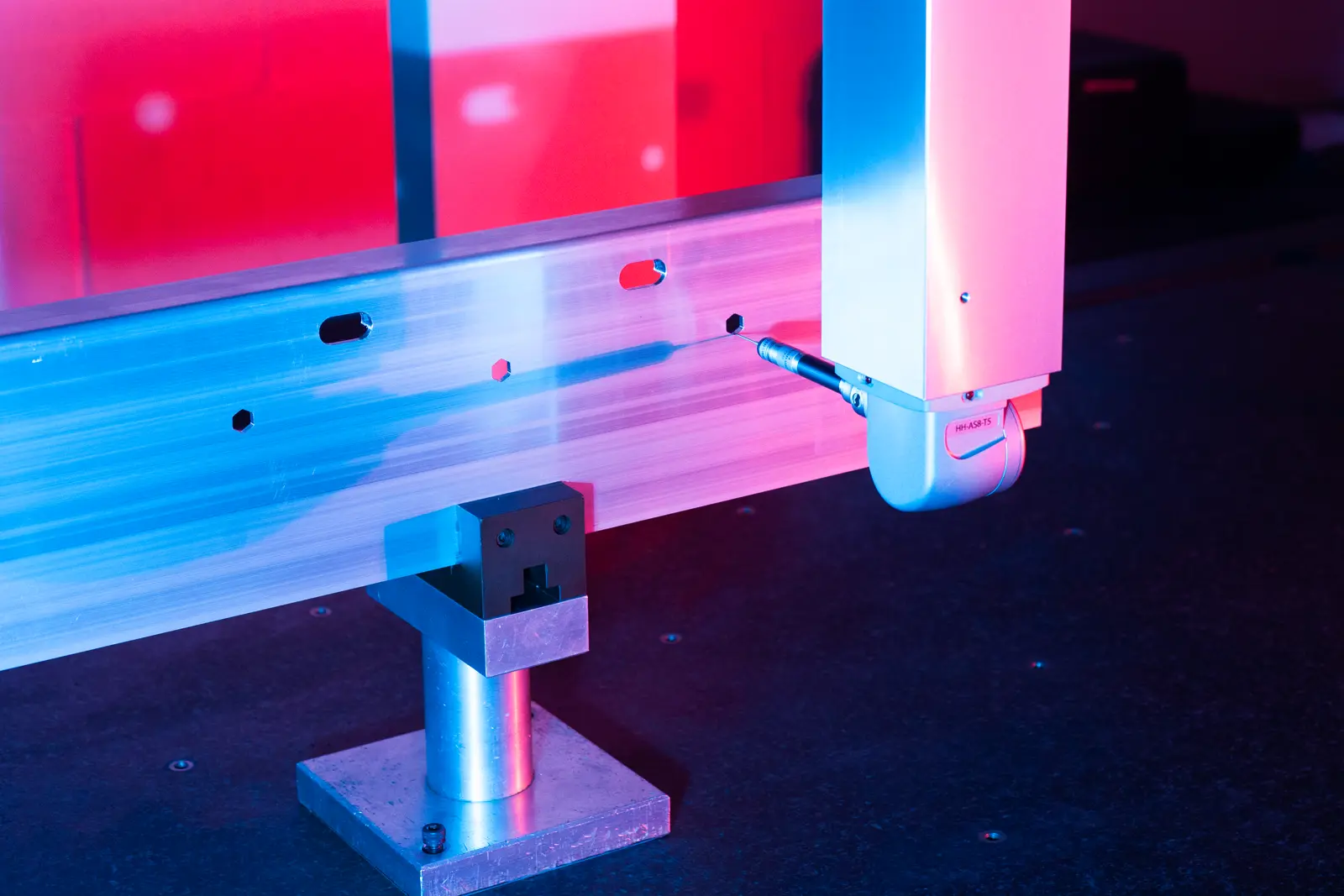

Stock is then processed using automated saws, precision profiling and CNC cutting systems, with every batch tracked through our ERP for full, digital traceability. Built on APQP methodology and PFMEA-driven risk assessment, our material flow ensures right-first-time quality, stable lead times and consistent performance across complex, multi-platform programmes.

Customer Benefits

Our customers benefit from:

- Certified sourcing of aluminium, steel, iron, titanium and specialist alloys from OEM-approved suppliers

- PMI-verified materials with full digital certification and batch traceability

- Precision preparation using automated sawing, CNC machining and profiling to reduce waste and machining time

- Real-time inventory visibility through ERP-linked batch identification

- PFMEA- and APQP-driven risk management for predictable quality and lead times

- A stable, controlled supply chain that supports cost-efficient, multi-programme delivery

Material Handling Capabilities

BCW’s Material Supply & Preparation facilities span our Burnley and Wellingborough operations, forming part of over 300,000 sq. ft. of vertically integrated UK manufacturing space.

Key facility features include:

- Dedicated receiving and inspection zones with PMI verification

- Automated horizontal band saws and precision profiling systems for accurate blanks and complex shapes

- Barcode-tracked inventory integrated with ERP for real-time material visibility

- Lean-flow layouts feeding machining, fabrication and treatment operations with minimal handling

This infrastructure ensures materials move seamlessly from certified suppliers to final production cells, maintaining integrity, reducing internal handling time and supporting consistent, repeatable quality across all programmes.

VerSATILE engineering services

Industries We Support

BCW’s precision manufacturing expertise supports OEMs and Tier 1 suppliers across:

Quality you can trust

Verified Through Rigorous Certification Standards

Our machining and inspection processes are certified to globally recognised standards.

Advanced Engineering Solutions

Facility

Our Precision Components Manufacturing operations span BCW’s Burnley and Wellingborough facilities, with over 300,000 sq. ft. of production space dedicated to CNC machining, automation, and precision inspection.

Each site operates under a unified quality system, ensuring repeatable standards across all programmes.

Key facility highlights include:

- Over 90 CNC machining centres, including multi-axis vertical and horizontal platforms

- Automated machining cells for high-volume continuous production

- Dedicated sliding head cell for small, complex parts

- Large component machining area with high-torque horizontal spindles

- Advanced metrology suite featuring CMM, FARO, laser trackers, and surface finish testing

Setting the Standard IN MANUFACTURING

Meet our specialist team

Let’s Engineer Success Together

Whether you’re developing new technology, scaling production, or strengthening your supply chain, BCW’s vertically integrated approach delivers precision, performance, and partnership at every stage.

Speak to one of our specialists