CAPABILITIES

Product Assembly

Where Precision Becomes Production

High-performance assembly solutions integrating machining, fabrication and surface treatments into complete, production-ready systems.

Product Assembly

Complete Builds Without Compromise

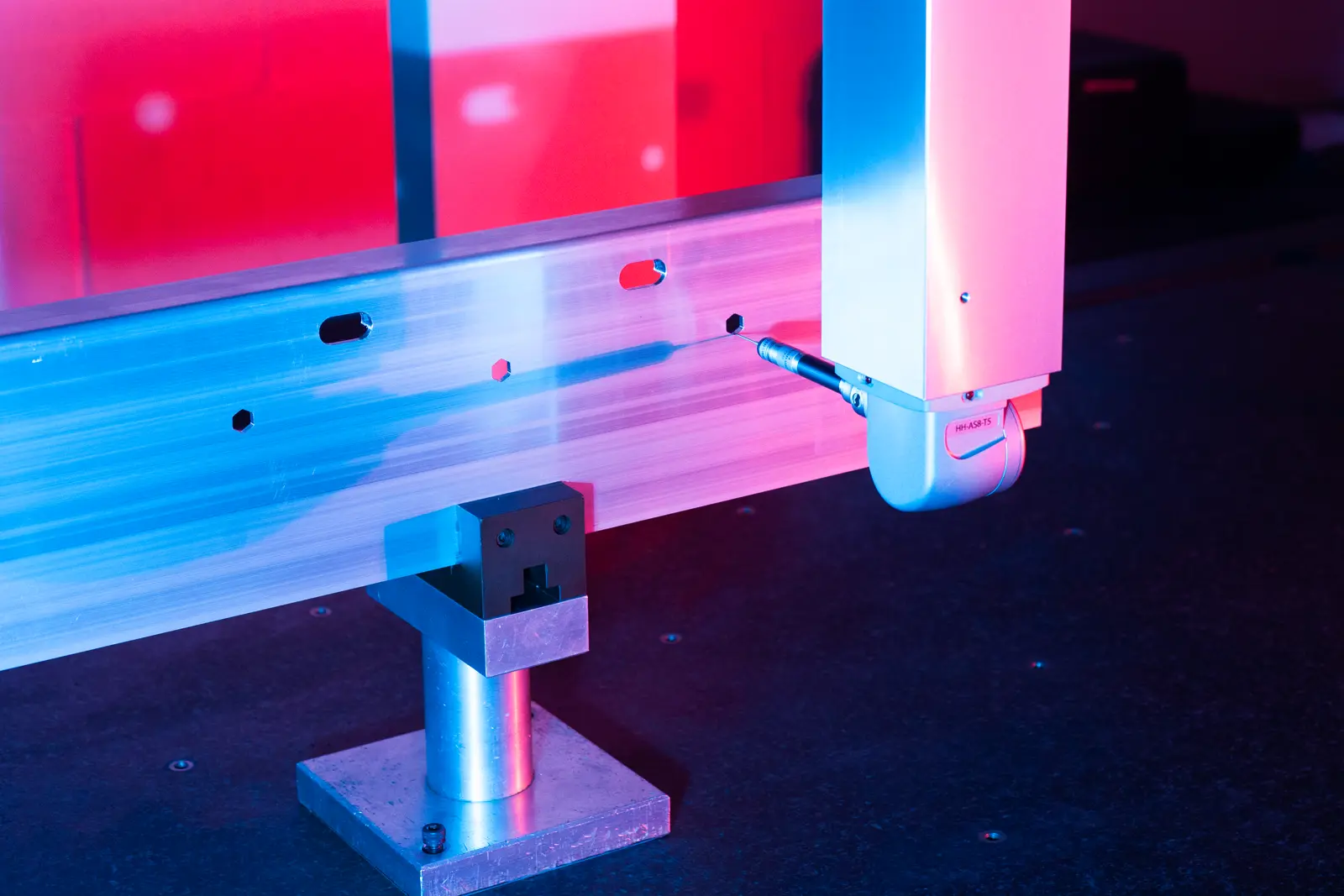

Product Assembly is the point at which BCW’s vertically integrated model comes together. It is where design, machining, fabrication and surface treatments transition into complete, production-ready assemblies built to perform in demanding technical environments.

From compact assemblies to large-scale systems, we deliver precision-engineered builds that meet stringent performance, safety and validation requirements. Through manual and robotic assembly applications, hydraulic and pneumatic presses and high-capacity assembly bays, BCW provides scalable solutions that streamline supply chains and accelerate time to market.

Lorem

XXX%

How We Do It

Assembly Expertise That Ensures Reliability

We combine engineering, precision assembly and automation under one roof to deliver robust, validated systems built to the highest standards.

Multidisciplinary teams work from 3D CAD models through to final assembly validation using laser tracking, automated torque systems and digital process control to guarantee right-first-time quality.

With fabrication, CNC machining, surface treatments and automation in house, BCW provides a closed-loop manufacturing process that reduces risk, lead time and total cost of ownership for OEM and Tier 1 partners.

Assembly and Integration

BCW’s assembly capability supports mechanical, hydraulic and pneumatic integration, enabling complete system build and validation in a controlled environment.

Our high-capacity assembly bays, laser-tracked alignment and purpose-built tooling ensure accuracy across assemblies of all sizes. CE-marked equipment, in-house lifting solutions and structured validation processes support safe handling and reliable performance for automotive, aerospace, defence and industrial applications.

Technical Features:

- 20-ton, 10-ton and 5-ton assembly bays

- Laser tracking

- Repeatable assembly tooling

- CE-marked equipment

- In-house lifting solutions

- Installation support

Fabrication and Material Expertise

Our assembly operations are supported by in-house fabrication and tooling capability, ensuring full control from concept to completion. We weld and fabricate aluminium, stainless steel and mild steel structures before integrating them seamlessly with CNC machining and surface treatments.

ERP-driven batch control provides full material traceability, while custom jigs and fixtures designed in house support both repeatable production and specialised assembly requirements across diverse programmes.

Technical Features:

- Welding and fabrication of aluminium, stainless steel and mild steel

- Integrated machining and surface treatments for complete build and finish

- Full material traceability through ERP-driven batch control

- Custom jigs and fixtures produced in house

Controls and Automation

BCW integrates intelligent controls and automation to enhance precision, repeatability and efficiency across assembly operations. Our team develops solutions from manual build systems to fully automated production cells, combining PLC programming, control panel design, robotics and poka-yoke inspection to improve productivity and quality.

Technical Features:

- PLC programming and control panels

- Pneumatic and electrical control systems

- Rotary indexing machines

- Collaborative robots

- Poka-yoke stations

- Vision systems for in-line verification

Through automation we help customers increase productivity, eliminate quality escapes and reduce operational cost.

Why Choose BCW As Your Assembly Partner

Key Differentiators

Vertically Integrated Advantage

CNC machining, fabrication, surface treatments, automation and assembly delivered by one organisation, reducing lead time and simplifying supply chain management.

Scalable and Flexible Capacity

From prototype and pilot builds to high-volume production, our facilities and overhead systems support programmes of any scale.

Proven Multi-Sector Expertise

Trusted by OEMs across automotive, aerospace, defence and off-highway, delivering precision-built components and complex CE-marked assemblies.

Innovation and Continuous Improvement

Lean principles, smart tooling and Industry 4.0 monitoring deliver gains in efficiency, repeatability and sustainability.

Intelligent Controls and Automation

In-house PLC programming, panel design, robotics, poka-yoke stations and vision systems that improve quality, consistency and productivity.

Partnership Mindset

We collaborate from concept to commissioning, developing tailored assembly and automation solutions that enhance quality, safety and programme performance.

Certified Quality and Traceability

Assembly validated through laser tracking, PFMEA and ERP-linked traceability, operating under ISO 9001, AS9100 D, IATF 16949 and ISO 14001.

VerSATILE engineering services

Industries We Support

BCW’s precision manufacturing expertise supports OEMs and Tier 1 suppliers across:

Quality you can trust

Verified Through Rigorous Certification Standards

Our machining and inspection processes are certified to globally recognised standards.

Advanced Engineering Solutions

Facility

Our Precision Components Manufacturing operations span BCW’s Burnley and Wellingborough facilities, with over 300,000 sq. ft. of production space dedicated to CNC machining, automation, and precision inspection.

Each site operates under a unified quality system, ensuring repeatable standards across all programmes.

Key facility highlights include:

- Over 90 CNC machining centres, including multi-axis vertical and horizontal platforms

- Automated machining cells for high-volume continuous production

- Dedicated sliding head cell for small, complex parts

- Large component machining area with high-torque horizontal spindles

- Advanced metrology suite featuring CMM, FARO, laser trackers, and surface finish testing

Setting the Standard IN MANUFACTURING

Meet our specialist team

Let’s Engineer Success Together

Whether you’re developing new technology, scaling production, or strengthening your supply chain, BCW’s vertically integrated approach delivers precision, performance, and partnership at every stage.

Speak to one of our specialists