CAPABILITIES

Fabrication

Engineered Strength. Fabricated With Precision

We deliver engineered fabrication solutions for demanding applications where structural integrity, accuracy and repeatability are critical.

Fabrication

Fabrication Engineered For Performance

From lightweight precision assemblies to multi-tonne structures, our fabrication specialists combine technical skill, welding expertise and disciplined process control to deliver parts that meet tight tolerances and functional performance requirements.

Accredited to EN 1090-1 EXC2, with welders certified to EN 9606-1/2 and ISO 3834-3, we produce high-integrity welds with proven repeatability. Continuous investment in tooling, training and digital verification ensures we support complex fabrication programmes with confidence, capability and precision.

Lorem

XXX%

How We Do It

How We Deliver Fabrication Quality

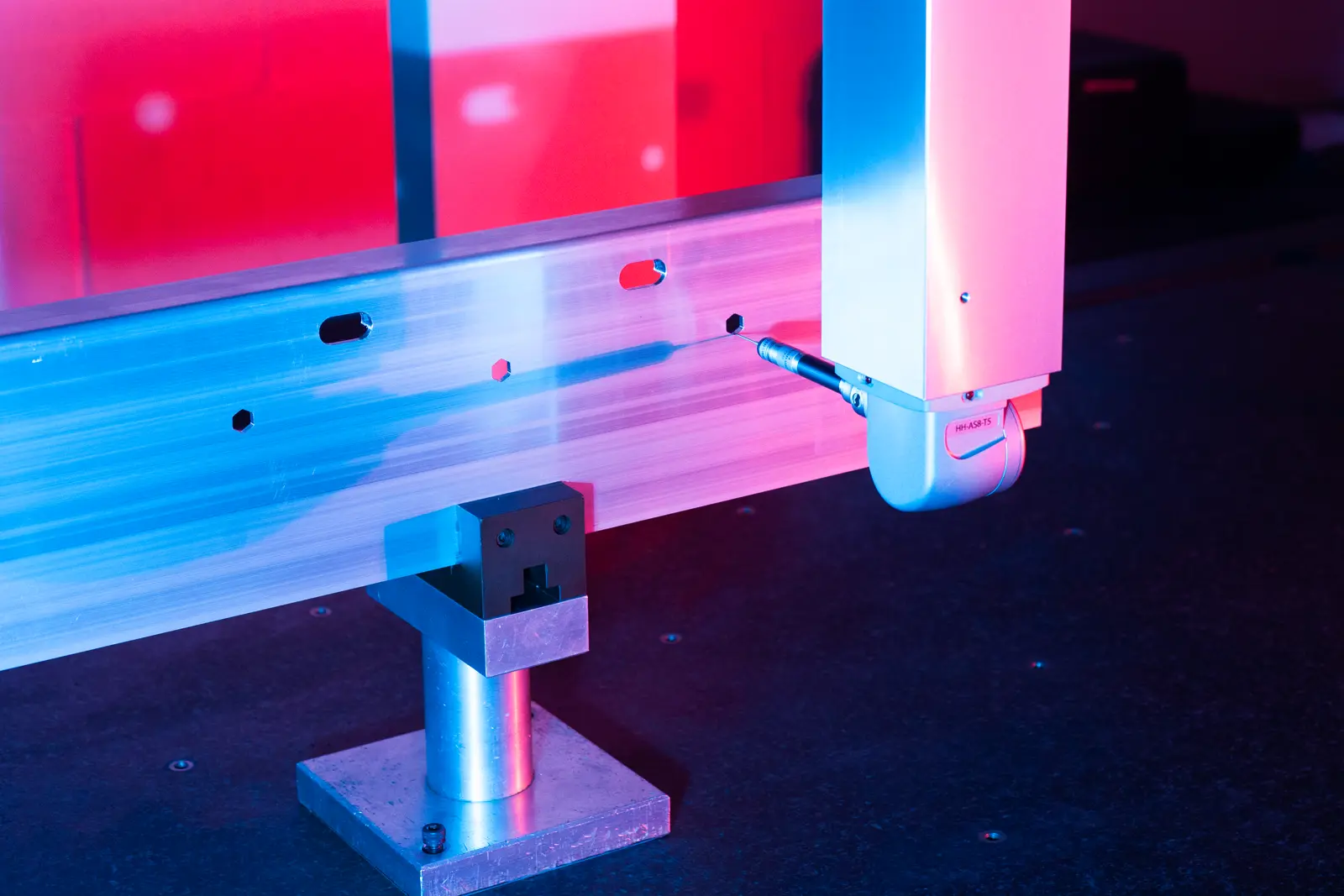

BCW’s fabrication process blends skilled craftsmanship with advanced machining, digital verification and structured quality control to produce robust, repeatable structures.

Working directly from customer CAD data, we manage fabrication, welding, machining and inspection in one controlled workflow, ensuring dimensional accuracy, weld integrity and functional performance.

Our vertically integrated model gives customers a single accountable partner for fabrication, treatments and assembly, reducing programme risk, improving supply-chain control and accelerating end-to-end delivery.

Material Expertise

Our fabrication and welding teams are qualified across mild steel, stainless steel, aluminium and Invar, enabling us to support structures requiring strength, stability, heat resistance or lightweight performance.

Each material group is managed under certified welding procedures, ensuring consistency and mechanical integrity across all assemblies. This broad material capability allows BCW to support diverse sectors, from automotive and aerospace to defence and industrial applications, delivering engineered solutions tailored to demanding operational environments.

Core Fabrication Processes

BCW delivers complete fabrication capability through controlled cutting, forming, machining and welding processes that ensure accuracy, repeatability and structural integrity. Each step is managed within a disciplined manufacturing environment, enabling consistent performance across every fabricated structure.

Process List

- Cutting: Precision cutting using laser cutting and sawing, waterjet and plasma profiling

- Forming: Rolling, pressing and stamping to achieve accurate radii, angles and geometry

- Machining: Milling, drilling and turning to refine interfaces and tolerances after fabrication

- Welding & Joining: MIG welding, TIG welding, brazing and mechanical fastening to create complex welded assemblies

Fabricated Products and Applications

Every product is built using controlled processes to ensure durability, accuracy and long-term performance.

Our capability includes:

- Assembly Fixtures: Precision-built for repeatable production

- Mould Tools: Robust tooling for forming and composite applications

- Checking Fixtures: Dimensional verification for accuracy and compliance

- Welding Fixtures: Engineered jigs for consistent welded assembly

- Ground Support Equipment: Load-bearing aerospace and industrial structure

- Lifting Frames & Transport Trollies: Certified handling solutions

- Marine Cradles: Corrosion-resistant support structures

- Heat Treatment Fixtures: High-temperature processing fixtures

Why Choose BCW for Fabrication

Skilled Coded Welders

Qualified to EN 9606 and EN 1090-1, ensuring consistent structural integrity across all material groups.

Engineering-Led Collaboration

We help refine designs, reduce cost and optimise manufacturability.

Seamless Vertical Integration

Fabrication, machining, treatments and assembly delivered as one accountable process.

Innovation and Continuous Improvement

Certified welding, controlled work environments and complete documentation.

Capability for High-Value, Complex Builds

From small precision parts to multi-tonne structures.

Reliable Delivery & Programme Performance

Lean workflows and experienced programme teams ensuring on-time, to-spec delivery.

Digital Verification & Documentation

Laser tracking, weld mapping and full ERP-linked traceability.

VerSATILE engineering services

Industries We Support

BCW’s precision manufacturing expertise supports OEMs and Tier 1 suppliers across:

Quality you can trust

Verified Through Rigorous Certification Standards

Our machining and inspection processes are certified to globally recognised standards.

Advanced Engineering Solutions

Facility

Our Precision Components Manufacturing operations span BCW’s Burnley and Wellingborough facilities, with over 300,000 sq. ft. of production space dedicated to CNC machining, automation, and precision inspection.

Each site operates under a unified quality system, ensuring repeatable standards across all programmes.

Key facility highlights include:

- Over 90 CNC machining centres, including multi-axis vertical and horizontal platforms

- Automated machining cells for high-volume continuous production

- Dedicated sliding head cell for small, complex parts

- Large component machining area with high-torque horizontal spindles

- Advanced metrology suite featuring CMM, FARO, laser trackers, and surface finish testing

Setting the Standard IN MANUFACTURING

Meet our specialist team

Let’s Engineer Success Together

Whether you’re developing new technology, scaling production, or strengthening your supply chain, BCW’s vertically integrated approach delivers precision, performance, and partnership at every stage.

Speak to one of our specialists