CAPABILITIES

Warehouse & Inventory

Control That Keeps Production Moving

Stable, visible and predictable material flow supporting prototype through to high-volume production.

EFFORTLESS PRODUCTION

Warehouse, Inventory & Supply Chain

BCW’s Warehouse, Inventory and Supply Chain capability forms the operational backbone of our vertically integrated model. We ensure materials, components and assemblies move through production with accuracy, visibility and control, protecting schedules and strengthening delivery performance.

ERP-driven stock management, flexible inventory strategies and proactive supply-chain planning ensure parts arrive exactly when required.

Whether supporting prototypes, launch phases or full serial manufacture, BCW removes complexity through strategic sourcing, supplier consolidation and delivery models such as JIT and Min-Max.

Lorem

XXX%

Precision Managed. Delivery Assured.

Our warehouse operations are engineered to maintain right-time availability, full traceability and uninterrupted material flow.

ERP planning and structured control processes govern inbound materials, WIP and finished goods with complete visibility.

From rapid prototype introduction to high-volume production, our warehouse team ensures every item is stored, tracked and delivered with accuracy.

The result is stable production flow, predictable scheduling and confidence that materials and assemblies are always where they need to be.

How We Do It

How We Manage Warehouse & Inventory

BCW manages warehousing and inventory with a focus on visibility, control and responsiveness.

Daily coordination with machining, fabrication, treatments and assembly ensures smooth progression through each stage without delays.

MRP-driven demand planning, KANBAN replenishment and visual management maintain accurate stock levels even during volatile programme phases.

This joined-up approach prevents shortages, stabilises inbound and outbound flow and consistently supports high on-time delivery performance throughout the programme lifecycle.

Technical Capability & Process Overview

Warehouse Operations

- Controlled storage for raw materials, WIP and finished goods

- ERP-driven stock management with real-time visibility

- FIFO and MRP-led replenishment

- Fast-track and prototype processing lanes

- Secure zones for high-value or sensitive parts

- Finished goods prepared for JIT, Min-Max and sequenced delivery

- Export documentation and international shipment coordination

Inventory Management

Our inventory strategy is designed around customer requirements, programme pace and risk profile.

BCW defines and manages the optimal model, Min-Max, JIT, safety stock or consignment, based on demand behaviour and production rhythm.

Full traceability is achieved through batch and serial tracking linked to ERP records.

During launch and ramp-up phases, we apply proactive inventory protection to maintain stable supply, reduce disruption and support smooth, uninterrupted production flow.

Logistics Solutions

- National delivery coverage across the UK

- Close proximity to Manchester, Liverpool and Leeds Bradford airports for global freight

- Collection and delivery aligned to customer build schedules

- Consolidated shipments reducing cost and environmental impact

- Rapid turnaround for prototype and urgent demand parts

- Sequenced packaging and line-side ready delivery

Supply Chain Management

Integrated. Responsive. Strategic.

BCW provides centralised supply chain coordination across machining, fabrication, treatments, assembly, warehousing and logistics.

This unified model eliminates fragmentation, strengthens schedule reliability and improves cost efficiency throughout the programme lifecycle.

Our supply chain team ensures every stage — from raw material acquisition to delivery of finished assemblies — is predictable, controlled and aligned.

The result is a secure, stable partnership for OEMs and Tier 1 customers requiring reliability at scale.

Strategic Supply Chain Capability

- Centralised coordination across all BCW UK operations

- Single-entry partner for manufacturing, treatments, assembly and logistics

- Supplier consolidation reducing POs, shipments and administration

- Local and global sourcing aligned to cost, quality and delivery targets

- Approved supplier network selected for reliability and technical capability

Programme Stability & Risk ManagementIntegrated. Responsive. Strategic.

BCW operates a proactive risk management model across materials, capacity and logistics.

We identify risks early and implement preventative measures before they impact production.

Flexible planning models absorb forecast variation, while enhanced supply protection supports early programme phases.

Dual and local sourcing strategies reduce exposure to single-point failures.

This stability ensures that production remains secure and uninterrupted, even in volatile market conditions or during accelerated ramp-up.

Customer-Centric Delivery Models

- JIT replenishment

- Min-Max inventory control

- Fixed-schedule delivery

- Line-side delivery

- Fully managed supply for multi-component assemblies

Why Choose BCW for Warehouse, Inventory & Supply Chain Integration

Vertically Integrated Control

One partner coordinating machining, treatments, assembly, warehousing and logistics.

Cost-Efficient Supply Chain

Supplier consolidation and integrated logistics reducing total acquisition cost.

ERP-Driven Visibility

Real-time stock accuracy ensuring predictable and reliable production flow.

Programme Security

Early risk management and supply protection safeguarding schedules.

Flexible Inventory Models

Designed for prototype, launch, ramp-up and full serial manufacturing.

Customer Partnership

BCW operates as an extension of your supply chain aligned to commercial and operational goals.

VerSATILE engineering services

Industries We Support

BCW’s precision manufacturing expertise supports OEMs and Tier 1 suppliers across:

Quality you can trust

Verified Through Rigorous Certification Standards

Our machining and inspection processes are certified to globally recognised standards.

Advanced Engineering Solutions

Facility

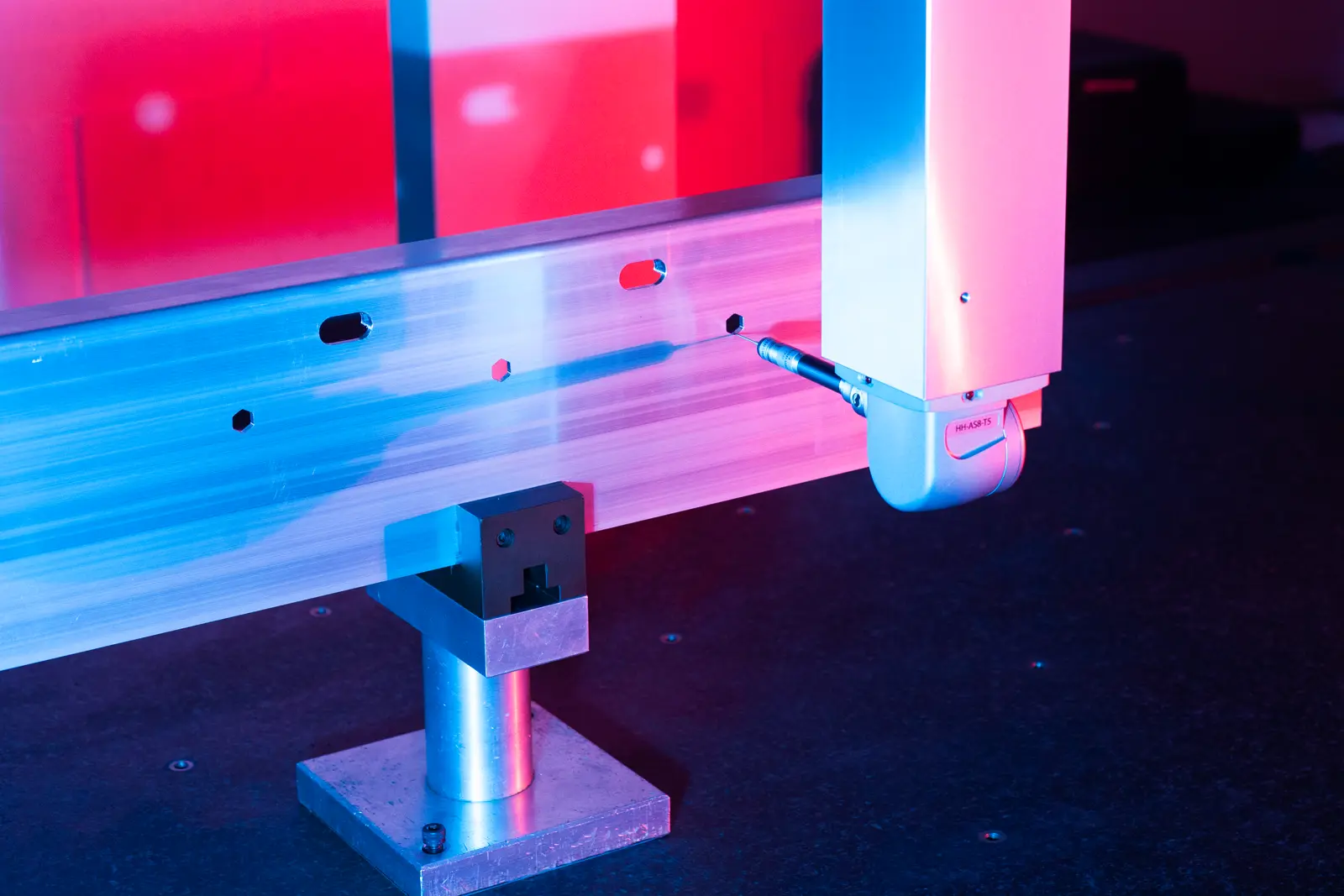

Our Precision Components Manufacturing operations span BCW’s Burnley and Wellingborough facilities, with over 300,000 sq. ft. of production space dedicated to CNC machining, automation, and precision inspection.

Each site operates under a unified quality system, ensuring repeatable standards across all programmes.

Key facility highlights include:

- Over 90 CNC machining centres, including multi-axis vertical and horizontal platforms

- Automated machining cells for high-volume continuous production

- Dedicated sliding head cell for small, complex parts

- Large component machining area with high-torque horizontal spindles

- Advanced metrology suite featuring CMM, FARO, laser trackers, and surface finish testing

Setting the Standard IN MANUFACTURING

Meet our specialist team

Let’s Engineer Success Together

Whether you’re developing new technology, scaling production, or strengthening your supply chain, BCW’s vertically integrated approach delivers precision, performance, and partnership at every stage.

Speak to one of our specialists