CAPABILITIES

Conceptualisation & Design

Design Engineered for Real Production

Digital design, simulation and engineering that eliminate rework and accelerate time to market.

Conceptualisation & Design

Design Collaboration That Drives Performance

BCW’s collaborative design model aligns engineering, quality and manufacturing from day one to ensure every component is optimised for functionality, cost efficiency and ease of production.

By validating design intent before tooling or machining begins, issues are resolved early, reducing change cycles and preventing costly downstream revisions. This integrated process delivers refined, production-ready solutions with full digital traceability, enabling faster approvals, improved programme stability and continuous improvement across the entire lifecycle.

Lorem Ipsum

XXX%

How We Do It

Validated Engineering From Concept to Production

BCW acts as a strategic design partner across NPI, prototype tooling and design-for-manufacture refinement.

Using CATIA V5, advanced FEA simulation and digitally linked FMEA, we evaluate structural performance, tolerance behaviour and manufacturability long before production begins. This early validation ensures robust, compliant and right-first-time outcomes for complex engineering programmes.

We support customers through:

- Digital validation and rapid prototyping

- Material and process selection guidance

- Tolerancing and manufacturability studies

- FEA simulation and FMEA reporting for audit traceability

Design Capability & Technical Environment

BCW’s design capability is based within our Burnley headquarters, forming the front end of more than 300,000 sq. ft. of vertically integrated manufacturing space across Burnley and Wellingborough. Our secure digital environment links directly to machining, fabrication and quality teams, enabling fast feedback, efficient approvals and full traceability from concept to production.

Design Infrastructure and Technical Systems:

- Secure CAD suites

- FEA, CFD and tolerance simulation

- Rapid prototyping

- Digital link to manufacture

- EN1090 design capability

Customer Benefits

Our customers benefit from:

- Early engineering involvement ensures right-first-time manufacture

- Rapid prototyping and digital validation accelerate time to market

- Integrated collaboration between design, quality and production

- Optimised balance of weight, stiffness, strength and cost

- Reduced rework and stronger programme efficiency

VerSATILE engineering services

Industries We Support

BCW’s precision manufacturing expertise supports OEMs and Tier 1 suppliers across:

Quality you can trust

Verified Through Rigorous Certification Standards

Our machining and inspection processes are certified to globally recognised standards.

Advanced Engineering Solutions

Facility

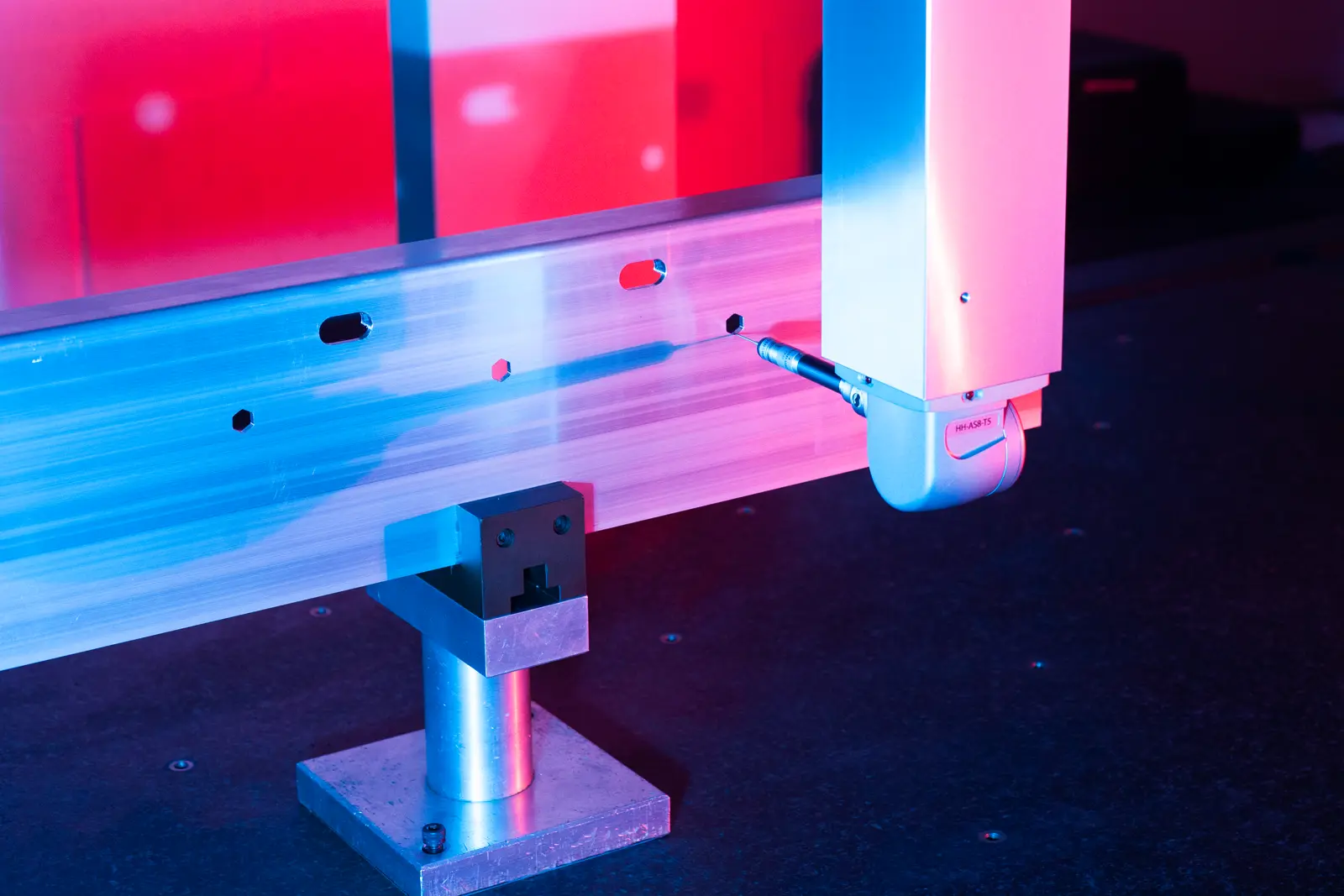

Our Precision Components Manufacturing operations span BCW’s Burnley and Wellingborough facilities, with over 300,000 sq. ft. of production space dedicated to CNC machining, automation, and precision inspection.

Each site operates under a unified quality system, ensuring repeatable standards across all programmes.

Key facility highlights include:

- Over 90 CNC machining centres, including multi-axis vertical and horizontal platforms

- Automated machining cells for high-volume continuous production

- Dedicated sliding head cell for small, complex parts

- Large component machining area with high-torque horizontal spindles

- Advanced metrology suite featuring CMM, FARO, laser trackers, and surface finish testing

Setting the Standard IN MANUFACTURING

Meet our specialist team

Let’s Engineer Success Together

Whether you’re developing new technology, scaling production, or strengthening your supply chain, BCW’s vertically integrated approach delivers precision, performance, and partnership at every stage.

Speak to one of our specialists