CAPABILITIES

Design for Manufacture

Optimising Design for Real-World Production

Design made manufacturable from day one, reducing cost, complexity, and time-to-production across the full BCW workflow.

Design-Driven Manufacturing

Engineering That Enables Production

At BCW, Design for Manufacture (DFM) ensures that every component is engineered for efficient, repeatable, and cost-effective production.

By aligning design engineering and manufacturing capability from the outset, we eliminate manufacturability issues before they reach the shop floor.

Our integrated approach reduces cycle times, cuts unnecessary complexity and ensures right-first-time quality, accelerating your programme from early feasibility through to volume production with confidence and control.

Lorem Ipsum

XXX%

How We Do It

Engineering Precision Into Every Detail

BCW’s DFM process combines design quality, manufacturing intelligence and real-time simulation at the start of every programme.

Using CATIA V5 and advanced FEA, our engineers analyse geometry, tolerance stacks, machining strategy, fixture access, and material use to optimise for production efficiency.

Structured DFM reviews, embedded within APQP, PFMEA and Control Plans, identify risks early and define robust, repeatable methods before parts reach the machine, ensuring stability from prototype to serial manufacture.

Customer Benefits

Our customers benefit from:

- Early manufacturability insights and feasibility studies

- Cycle-time and product-cost reduction through optimised processes

- Tolerance stack-up analysis for accuracy and repeatability

- Risk-managed production using PFMEA and APQP

- Smooth transition from prototype to volume production

- Long-term collaboration through integrated engineering support and continuous improvement

VerSATILE engineering services

Industries We Support

BCW’s precision manufacturing expertise supports OEMs and Tier 1 suppliers across:

Quality you can trust

Verified Through Rigorous Certification Standards

Our machining and inspection processes are certified to globally recognised standards.

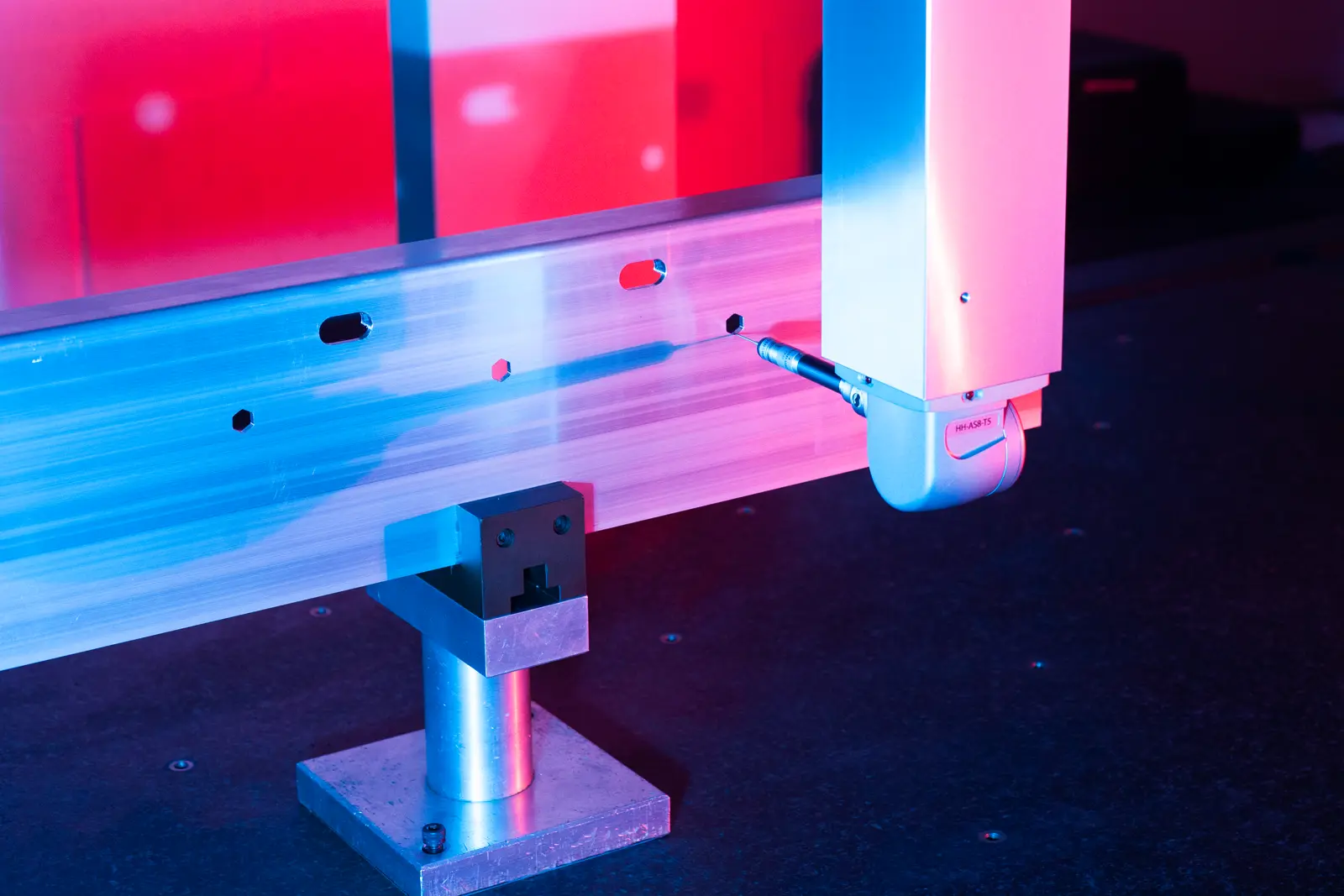

Advanced Engineering Solutions

Facility

Our Precision Components Manufacturing operations span BCW’s Burnley and Wellingborough facilities, with over 300,000 sq. ft. of production space dedicated to CNC machining, automation, and precision inspection.

Each site operates under a unified quality system, ensuring repeatable standards across all programmes.

Key facility highlights include:

- Over 90 CNC machining centres, including multi-axis vertical and horizontal platforms

- Automated machining cells for high-volume continuous production

- Dedicated sliding head cell for small, complex parts

- Large component machining area with high-torque horizontal spindles

- Advanced metrology suite featuring CMM, FARO, laser trackers, and surface finish testing

Setting the Standard IN MANUFACTURING

Meet our specialist team

Let’s Engineer Success Together

Whether you’re developing new technology, scaling production, or strengthening your supply chain, BCW’s vertically integrated approach delivers precision, performance, and partnership at every stage.

Speak to one of our specialists