CAPABILITIES

Surface Treatments

Protecting and Enhancing Every Component

Surface treatment is one of the most critical, stages of BCW’s vertically integrated manufacturing process because final performance, durability and compliance depend on the quality of the finish applied.

Surface Treatment Specialist

Built To Perform

At BCW Treatments, we specialise in performance-driven finishing solutions engineered to protect, enhance and extend component life across automotive, aerospace, defence and other industrial applications. Our treatments improve corrosion resistance, strengthen adhesion, enhance electrical insulation and deliver consistent visual quality.

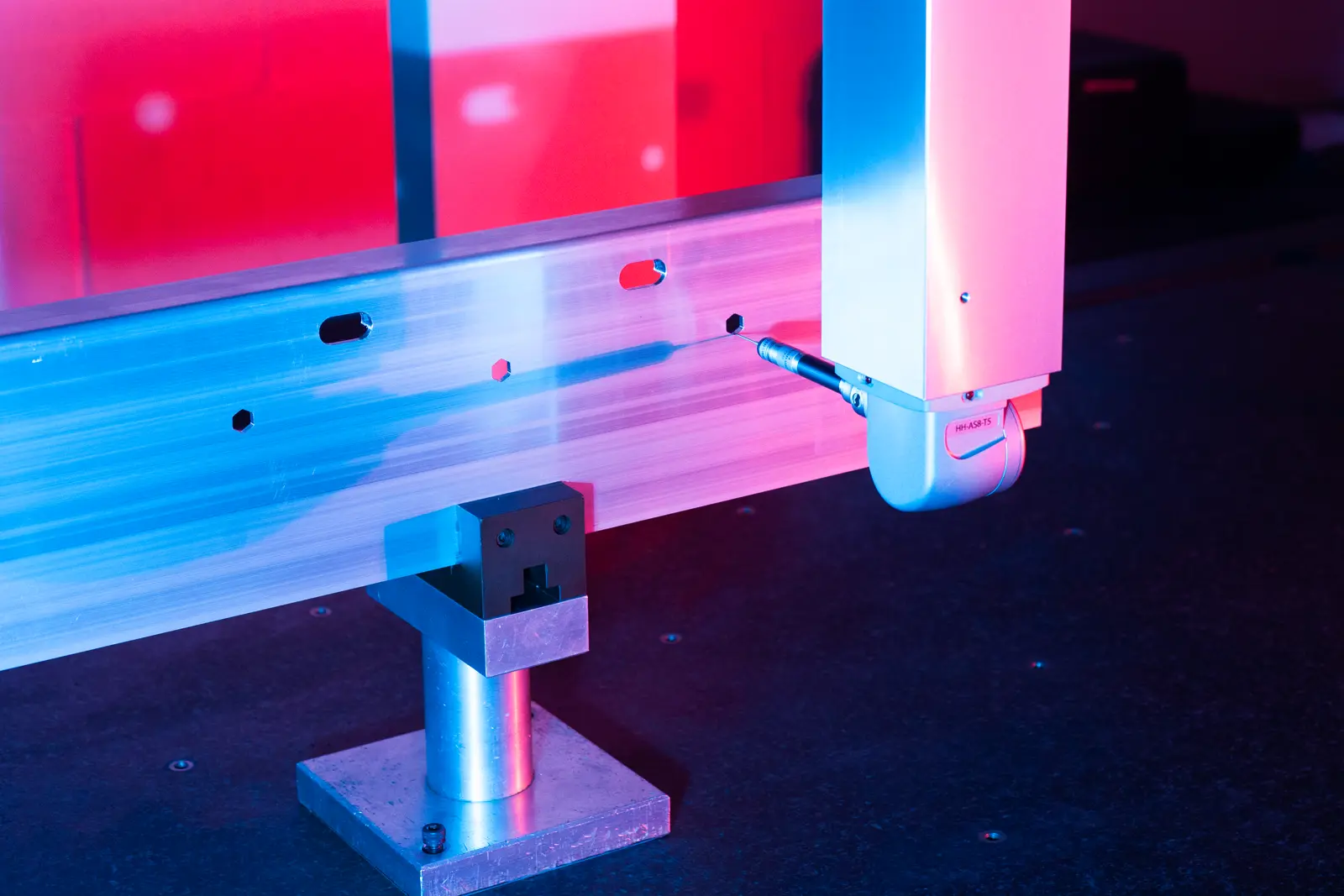

Every process is controlled, validated and executed in-house to guarantee repeatability and reliable throughput. With automated systems and dedicated laboratory support, we ensure every component performs exactly as required, from precision assemblies to high-volume OEM programmes.

components treated annually

5 million

How We Do It

Protecting Performance, Enhancing Quality

BCW delivers a fully integrated surface treatment capability built around automation and scientific process control. All treatments are designed, managed and validated in-house, ensuring that every component receives the correct finish for its functional, aesthetic and environmental requirements.

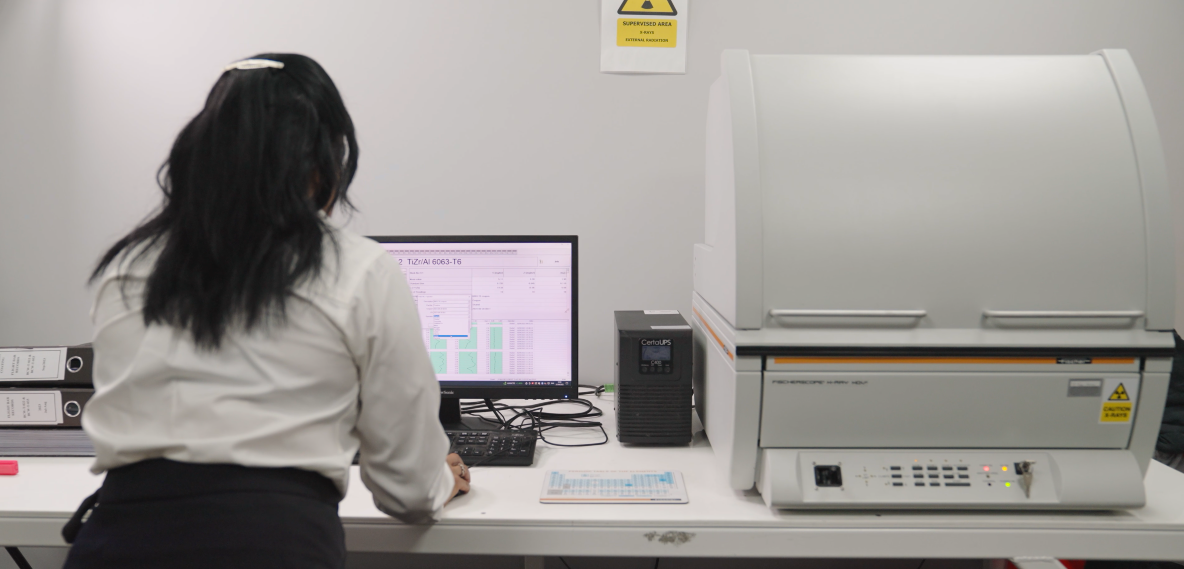

Our dedicated laboratories verify coating weights, chemical analysis and adhesion performance, while full automation ensure consistent quality across high-volume production. This closed-loop approach guarantees accuracy, repeatability and supply-chain reliability across every programme.

Aluminium Anodising (Type II Sulphuric Acid)

BCW’s Type II sulphuric anodising provides a durable, corrosion-resistant and aesthetically enhanced finish ideal for automotive, aerospace and defence components.

Our automated anodising line ensures consistent coating growth, colour stability and controlled pore structure for improved paint and adhesive bonding. In-house jigging and laboratory analysis guarantee precise film thickness, coating weight and surface integrity.

Specifications: MIL-A-8625, DEF STAN 03-25, BS EN ISO 7599, BS EN 12373.

Ideal for: lightweight structures, exterior trims, high-wear components, bonding applications.

Conversion Coating (Passivation)

BCW provides conversion coating for ferrous and non-ferrous components, producing a uniform, adherent surface film that enhances corrosion resistance and optimises adhesion for downstream coatings, paints and bonding processes.

Our Titanium Zirconium and Zinc Phosphate systems deliver consistent, high-quality surface preparation that supports demanding automotive and industrial programmes. Automated processing ensures repeatable performance, while in-house laboratory testing verifies film weight, adhesion and surface integrity to OEM and international standards.

Specifications: TiZr, Zinc Phosphate, MIL-DTL 5541

Applications: sub-assemblies, bonded components, pre-paint treatments and high-volume production parts.

Powder Coating

BCW’s powder coating capability provides a durable, uniform and environmentally efficient finish for components exposed to demanding operating environments. Our automated booths, controlled curing processes and in-house jigging ensure consistent coverage, film build and adhesion. We support a wide range of colours, textures and performance grades, including anti-corrosion and high-durability formulations.

Specifications: BS EN 12206, AAMA 2603/4/5

Applications: Off-highway, Automotive & Defence components, high-volume industrial products, fabrications and fabricated assemblies.

Electrostatic Wet Paint

BCW’s electrostatic wet paint capability delivers precision-controlled finishes across complex geometries and multi-material components. Using the latest Wagner electrostatic systems, automated mixing technology and in-house engineered jigging, we achieve uniform film thickness, excellent wraparound coverage and high transfer efficiency.

Our process ensures superior adhesion, outstanding surface consistency and reduced overspray, supporting demanding applications in automotive, aerospace, defence and industrial sectors. Every coating is validated through laboratory testing to meet strict OEM and international performance standards.

Specifications: 2K Paint System include Base & Actuator/Hardener.

Applications: Engine mounting & structural brackets, pullies, hubs & rotating ancillaries, small to medium steel fabrications

Defence Specialist Coatings

BCW Treatments delivers defence-grade finishing solutions engineered for extreme environments, operational reliability and long-term durability.

Our coatings enhance chemical agent resistance, reduce reflectivity and improve component longevity across land, sea and air platforms. All processes follow strict defence and aerospace standards, supported by controlled processing, full traceability and laboratory verification.

Specifications: UK MOD CARC coatings meeting DEF STAN 80-161 and 80-225, AMS STD 595

Applications: Armoured vehicle components, marine hardware, aerospace fixtures, electrical housings and mission-critical assemblies

Dielectric Coating

Our dielectric coating systems provide high-performance electrical insulation for EV, battery, powertrain and electronics applications.

Controlled, repeatable processing ensures consistent dielectric strength, stable resistance and precise film thickness across varied geometries. Laboratory testing verifies insulation performance, adhesion and thermal/environmental stability, enabling OEMs to improve safety, reduce weight and enhance system reliability.

Specifications: BS EN 12206, AAMA 2603/4/5

Applications: battery housings, busbars, electrical connectors and power electronics requiring reliable insulation under thermal and mechanical load.

Integrated Control & Traceability

Every BCW process is controlled, validated and fully traceable through our advanced quality management systems. In-house laboratories verify coating weight, film thickness, adhesion and corrosion resistance using calibrated test equipment.

Statistical process control (SPC) ensures repeatability, while all treatments operate to strict OEM and international specifications. From incoming inspection to final validation, every stage is documented for supply-chain confidence and programme stability.

- Full batch traceability

- SPC-driven process optimisation

- In-house laboratory verification

- Compliance with automotive, defence, off-highway, aerospace, rail, power generation

Research, Innovation & Technical Expertise

Our dedicated R&D function, supported by two PhD specialists and partnerships with leading UK universities, continually advances coating technologies for improved adhesion, durability and sustainability. By combining scientific research with production expertise, we help OEMs stay ahead of evolving standards and engineer finishes that deliver proven, long-term performance.

- University-led collaborative research

- Advanced material science expertise

- Sustainability-focused process innovation

Benefits to the Customer

Vertically Integrated Expertise

A single partner solution

Controlled, Repeatable Processing

SPC-led process optimisation and laboratory validation

OEM-Approved Quality Standards

Operating under ISO 9001, IATF 16949, ISO 14001 and JOSCAR

Specialist Technical Support

In-house materials scientists, PhD expertise and engineering collaboration

Reliable Prototype to Volume Production Capability

Supporting OEM programmes with stable throughput and repeatability

End-to-End Traceability

Documented process visibility, batch-level tracking and complete supply-chain assurance

VerSATILE engineering services

Industries We Support

BCW’s precision manufacturing expertise supports OEMs and Tier 1 suppliers across:

Quality you can trust

Verified Through Rigorous Certification Standards

Our machining and inspection processes are certified to globally recognised standards.

Advanced Engineering Solutions

Facility

Our Precision Components Manufacturing operations span BCW’s Burnley and Wellingborough facilities, with over 300,000 sq. ft. of production space dedicated to CNC machining, automation, and precision inspection.

Each site operates under a unified quality system, ensuring repeatable standards across all programmes.

Key facility highlights include:

- Over 90 CNC machining centres, including multi-axis vertical and horizontal platforms

- Automated machining cells for high-volume continuous production

- Dedicated sliding head cell for small, complex parts

- Large component machining area with high-torque horizontal spindles

- Advanced metrology suite featuring CMM, FARO, laser trackers, and surface finish testing

Setting the Standard IN MANUFACTURING

Meet our specialist team

Let’s Engineer Success Together

Whether you’re developing new technology, scaling production, or strengthening your supply chain, BCW’s vertically integrated approach delivers precision, performance, and partnership at every stage.

Speak to one of our specialists